IZOPRON WITH PENETRATING WATERPROOFING EFFECT

RANGE OF APPLICATION

RANGE OF APPLICATION

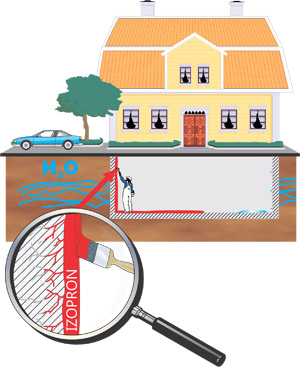

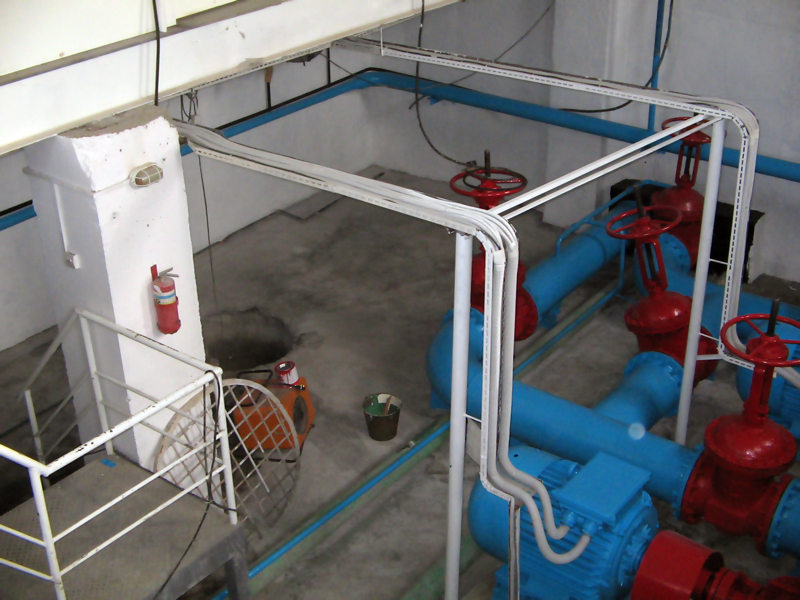

IZOPRON is used for waterproofing foundations, subbasements, pools, concrete tanks, etc.

IZOPRON is mainly designed for interior waterproof protection of prefabricated structural units against subsoil waters without additional development of drains and outside perimeter ditching.

IZOPRON penetrates into concrete surfaces, and waterproofs them so as to prevent fungi accumulation and expansion.

IZOPRON restores and reinforces defective concrete surfaces, considerably enhances overall strength, water and freezing resistance, and durability.

OPERATING PRINCIPAL

Active components of "IZOPRON" penetrate into concrete due to capillary suction and osmotic diffusion forces and along with water, enter into a reaction with concrete hydrated cement, and form water-nonsoluble whiskers. These whiskers fill concrete pores, capillaries and micro-cracks with high density and penetrating depth, consolidate structures, and render the concrete waterproof and resistive to aggressive medium impact.

IZOPRON becomes a part of the concrete forming a solid, strong, long-life structure, retaining air permeability.

SAFETY AND LABOR PROTECTION

SAFETY AND LABOR PROTECTION

When treating the operating mix it is necessary to wear rubber gloves, protective breathing equipment, and protective goggles. Rubber gloves should be worn when applying the IZOPRON mix solution. In case of contact with skin or eyes the affected areas should be washed with a large amount of water.

STORAGE

IZOPRON should be stored in dry premises, inside the Manufacturer's packs. Maximum stock height for storage and shipping is 3 buckets. In the case of damage to the Manufacturer's pack or the remainder of dry material post-work, put the material into the sealed container.

TEMPERATURE CONDITIONS

Work should be done at a temperature no lower than +5°C.

PACK

IZOPRON is delivered powdered, in 12kg buckets.

STORAGE PERIOD

12 months from the date of manufacturing inside intact Manufacturer's packs.

WASTE DISPOSAL

Waste disposal of IZOPRON diluted mix should be performed in conformity with regulations and requirements to cement contained material disposal. It is strictly forbidden to throw material remains in the sewerage system or to bury them in soil.

Way of use:

|

|

|

1. SURFACE TREATMENT

Focal factor: structurally firm base, capillary porosity opening. The surface should be cleared of weak, low-cement plaster, easy removable inclusions, paint, whitewash, dirty, fat, cement stone surface films, etc, - using metallic brushes or powered machines - with the help of a perforator, electric drilling machine, waterjet machine, etc.

Concrete structure joints (ceiling panel to wall joints, horizontal and vertical joints, foundation blocks joints) should be rejointed to a depth of at least 30 mm with grooves (at right angle) of at least 20 mm with the perforator.

Bare reinforcements should be ground to free them of dirt and rust. The surface must be washed down with ordinary tap water until grinding remains have been completely removed.

Warning: prior to "IZOPRON" application the surface must be saturated with as much water as possible.

2. MORTAR PREPARATION

Pour an amount of the mix required for 40-60 working minutes into the user-friendly container. Hydrate with water of room temperature in the following ratio: no more than 250ml of water per 1 kg of mix; agitate carefully using the electric drilling machine equipped with the blending bit (or mixer) for 5 minutes without adding water. The mix is ready for work when it is homogeneous and plastic. When working, periodically perform extra agitation of the mix without adding water.

3. TREATMENT OF CONCRETE AND CONSISTENT PLASTERED (MULTI-CEMENT) SURFACES

Prefabricated "IZOPRON" mix should twice be applied "crosswise" to water-saturated surfaces with a brush made of synthetic fibres. This should be done with a time interval of at least 30 minutes but no more than 4 hours. Material consumption is specified on the basis of up to 1.5 kg per square meter to apply two layers on the flat surface. Before applying the first layer it is necessary to seal up all joints, seams, cracks, dents, engineering connections, etc. (refer to SEALING OF JOINTS).

4. SEALING OF JOINTS

Add sand to "IZOPRON" dry mix in a ratio of 1 IZOPRON to 3 sand, hydrate with water, and agitate carefully to obtain homogeneous and plastic mix solution. The sanded mix solution should be preliminary slugged into advanced rejointed and moistened joints (refer to SURFACE TREATMENT). After the solution sets (the time interval depends on air temperature and humidity) treat the joints with brush solutions without sand.

5. PLUGGING PRESSURE LEAKS

Drill the leak spot in the form of a cone with the base directed to the wall using a perforator or the drilling machine. Add gypsum cement to "IZOPRON" dry mix (quick-hardening) in a ratio of 1 IZOPRON: 2 gypsum cement, and agitate carefully with the water to obtain homogeneous and plastic mix solution of doughy texture. Just after agitating make a ball (cylinder) out of the finished mass, and when setting starts force it into the opening with active motions. The remaining unfilled part of the opening (groove) should be filled with "IZOPRON - sand" mix solution (ratio 1:3). Finish edges to a true surface. After drying, apply pure IZOPRON mix solution by the brush.

6. PLASTER WATERPROOFING OF BRICK SURFACES

For waterproofing non-plastered brick and stone surfaces it is necessary to use "IZOPRON" to prepare waterproofing plaster mix. Agitate 1 part of IZOPRON and 3 parts of sand with water without adding cement to obtain thick homogeneous and plastic mix solution. The mix solution prepared in such a way should be applied with a spatula on the treated surface simply as a plaster with a layer thickness of no more than 1 cm.

Then pure "IZOPRON" brush layer should be applied on the surface according to the method specified in Section 5.

7. COATING CARE

Indoor "IZOPRON" waterproofing layer must be water sprayed 2-3 times per day for 2-3 days (care as for fresh concrete). Outdoor in order to prevent fast drying, IZOPRON treated surface must be covered with a film.

8. FOLLOWING USE OF THE WATERPROOF COATING

After 7 days from the date of application of "IZOPRON" waterproof layer, the surface can be used as a base for decorative tiles, parquet, paints, plasters, etc.

The premises where the waterproofing has been done must have good ventilation or airing. Otherwise the indoor air water, which would have penetrated into the surface without IZOPRON application, will now remain on the surface because IZOPRON works as a waterproof barrier

|

|

|

|

Оставить свой отзыв вы можете на оффициальной странице организации SUHO (en),

расположенной на информационном ресурсе open-krasnodar.ru.

Перейти на страницу.

Оставить свой отзыв вы можете на оффициальной странице организации SUHO (en),

расположенной на информационном ресурсе open-krasnodar.ru.

Перейти на страницу.